so this was the first repair to clue me in to the ceramic package cold solder issue. i had been chasing a “bump its fixed” bad receive issue. every so often the SSB receive would drop down to no S meter reading and barely audible for even nearby 20 over signals. a good bump would fix it for ahile, then it would drop out again. after opening the case, resoldering any suspicious joints in the area, closing back up maybe two dozen times, i finally removed the shield over the DDS unit. pressing on the PCB around it seemed to have the greatest effect on the cutout.

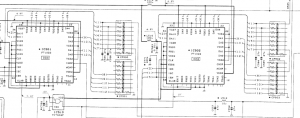

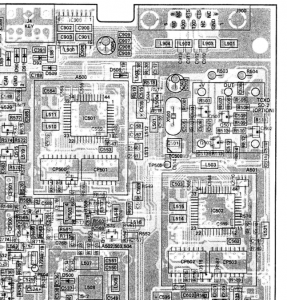

thiere are two direct digital synthesiser units in the ts-570. they consist of an extinct custom chip F71022 and two ceramic pack precision resistor ladders. they are ic501 and 502 are the DDS, and CP500 CP501 CP502 CP503 are the four packs. my guess, the ceramic packs are only side soldered and heat expansion delta from the epoxy PCB cracks the joints. normally surface mount components do not get cold solder issues, its the hand soldered bigger parts and jacks usually. but these are like little ceramic circuit boards on top of the regular epoxy board and they dont stretch and contract the same. i reflowed cp500 and 501 that go with ic501 which gens the 8.83mhz carrier to the mixer and that cleaned it right up. pushing on the pcb no longer cut the SSB. these ceramic packs are in bunches of kenwood radios from 80’s onwards as they are very precision and probably temp stable too. tm-733 uses one for PL tone generator, ts-950sdx has same double DDS chips same packs, etc.

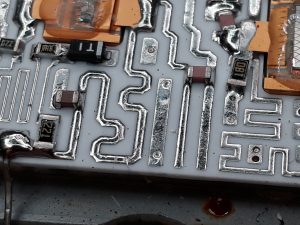

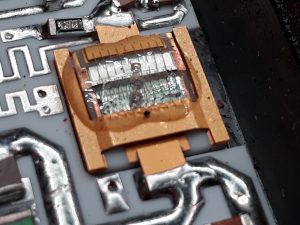

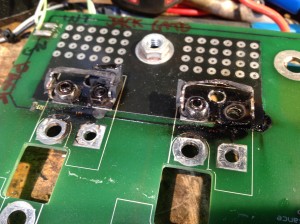

i know not best pic, but here is the dds unit w shield off. other dds is top left still under metal,shield. here looking at tx/rx board, serial jack top right, dds is big square chip in middle, and the resistor packs are to the left of the DDS with red lettering. i used a 1/64″ tip soldering iron, smeared flux on both sides of the packs, no solder, just touched each “notch” on the sides that is the contacts. no real legs or leads, just conductive paint goes from top of pack over the side edge. not sure if it continues under the pack. carefull not to scrape this paint off, and go in hot and fast and get out cuz the ceramic sucks